We produce among the finest natural cork stoppers in the world. Their quality and consistency make them the preferred enclosure for dozens of elite and iconic wineries around the globe. Below are some of the key attributes that distinguish Parramon from our competitors.

- Controlled Sourcing ‑ All cork bark wood is personally sourced by the Managing Director, Francesc Parramon.

- Only the Best Wood – Over the last six decades, the Parramon family has established deep relationships with Spain’s top cork growers. We buy only the highest grades of wood to guarantee the ultimate closure.

- Optimum wood aging– While the industry as a whole holds their wood outdoors for 6-12 months prior to production, we age our wood for 12-18 months beneath protective structures. This extended maturation (as with barrels) removes green wood characteristics and allows the wood phenolics to mature. It also allows for more homogenous density which helps eliminate visual defects such as ovalization, cracks and green wood.

- Total traceability – We only work with one purchased lot of cork at a time. There is no blending of wood sources or production lots to make a certain quality. Every cork can be traced back to the original grower and forest.

- Unique sanitization ‑ Prior to entering the production facility, all wood is subject to a patented ozonated water shower to cleanse and sanitize the material. This is far superior to the dirty and contaminating batch boiling processes used by larger industrial producers.

- Clean Water – Batch boiling uses the same water over and over which can lead to cross contamination. We only use our shower water once and then sell it for to the local municipality irrigation use.

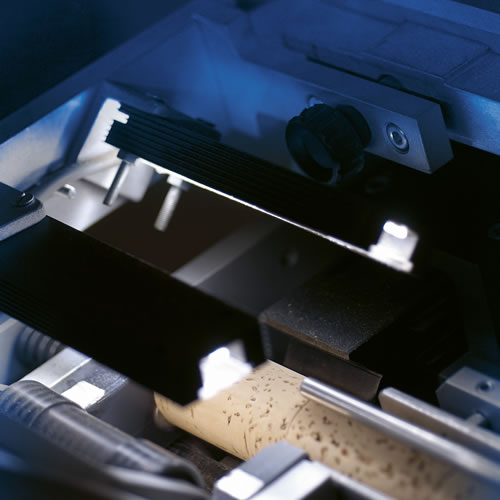

- Automation ‑ Once sanitized, the wood enters the production area where all production processes are automated. All bark is cut into strips, punched and sorted by machine. This eliminates human error and increases efficiencies.